博格华纳:P2混动驱动模块

产品名称:P2混动驱动模块

推荐企业:博格华纳

P2 Modules

技术特点

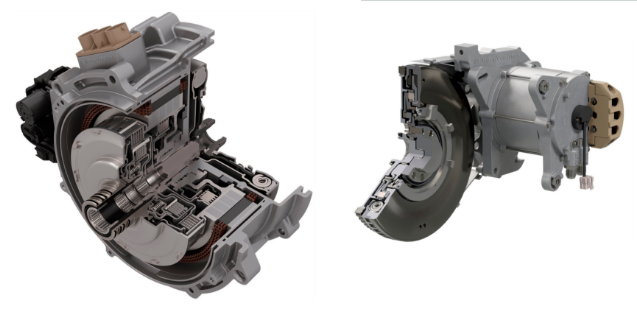

博格华纳的同轴式 P2 驱动模块将电机直接置于内燃机和变速器之间,可以兼容现有的车辆平台,实现经济的动力混合。这种创新的 P2 解决方案能够集成多达三个离合器,其中包括一个断开离合器,它允许系统与发动机分离以实现纯电动驾驶,使得客户能够实现各自所需的燃油效率和性能目标。此外,博格华纳还可提供用于起动湿式离合器的电液压控制装置,客户可选择单个的部件或完整的系统。

博格华纳的 P2 驱动模块也可提供偏置式构型。这种设计将电机与主轴平行放置,并通过博格华纳某款耐用链条技术连接系统,以确保最大的扭矩传递。

博格华纳 P2 驱动模块使 OEM 能够以同轴或偏轴式构型,将电机灵活地置于现有的架构中。它采用博格华纳屡获殊荣的 S型绕组导线成型工艺来制造电机,通过其紧凑的封装获得较高功率和扭矩密度。此外,与使用皮带连接系统的其他 P2 偏轴式解决方案不同,博格华纳的偏轴式驱动模块通过某款高强度和高耐用的静音型链条传动技术连接 P2,从而提供最佳的性能。而且,该解决方案还提供停止/启动、再生制动和补充电力推进功能,适用于 48 伏及高压混动系统。

市场表现

.目前已经有几家OEM选择使用了博格华纳P2混动驱动模块,如长安、海马。

.可扩展性—MHEV到PHEV

.性能—具有再生功能的全电驱动能力

.灵活性—主机厂已经投资的变速器和发动机产线可高重复利用率

.效率-允许制动能量的高回收率

.拥有完整的模块化的同轴/偏置式48V和高压系统P2模块

.兼容A/T、DCT、CVT和DHT

.利用S-Wind电机进行紧凑设计

.完全混合,投资最少

.在未来5年,P2混合动力驱动模块将成为领先的电子驱动推进

.系统。我们估计到2024年,全球混合动力汽车将达到3200万辆,P2混合动力驱动模块将占15%,即480万辆。博格瓦纳能够为P2混合动力驱动模块提供全面的解决方案,包括三重离合器模块、控制模块、减振器、P2电机、电力电子和软件。

.不断接触国内外OEM

.提供从零部件到模块到集成系统的解决方案

.提供紧凑且性价比高的P2混动驱动模块

By placing the electric motor directly between the internal combustion engine and the transmission, BorgWarner’s on-axis P2 drive module delivers cost-effective hybridization by being compatible with existing vehicle platforms. The innovative P2 solution offers the possibility of integrating up to three clutches, including a disconnecting clutch, which allows the system to decouple from the engine for pure electric driving, enabling customers to achieve both their individual fuel-efficiency and performance goals. In addition, BorgWarner can supply the electrohydraulic controls for actuating the wet clutches, giving customers the option to choose individual components or a complete system.

BorgWarner’s P2 drive module is also available in an off-axis configuration. This design places the electric motor parallel to the main axis and connects the system via one of the company’s durable chain technologies, ensuring maximum torque transfer.

The company’s P2 drive modules give OEMs the flexibility to place the electric motor where they have space in existing architectures, either on- or off-axis. By using BorgWarner’s award-winning S-wind wire-forming process to create the motor, the P2 drive module produces high power and torque densities in an extremely compact package. In addition, unlike other off-axis P2 solutions that use a belt to attach the system, BorgWarner’s off-axis drive module delivers top performance from connecting the P2 via one of its best-in-strength and durability, quiet, chain drive technologies. Moreover, the solution offers stop/start, regenerative braking and supplemental electric propulsion, and is available for 48-volt and high-voltage hybrid systems.

Many big OEMs has choosed BorgWarner P2 hybrid drive module, such as Changan, Haima

Scalability – MHEV to PHEV

Performance – Full e-Drive capability with regeneration

Flexibility – High reuse of invested base transmission and engine content

Efficiency – Allows high recuperation of the braking energy

Comprehensive, modular kit for On and Off Axis 48V and High Voltage systems

Compatible with A/T, DCT, CVT and DHT

Leverage S-Wind motor for compact design

Full hybridization with minimal investment

Over the next 5 years, P2 hybrid drive modules become leading e-Drive propulsion system. We estimate by 2024, hybrid vehicle all over the world will be 32 Million, P2 hybrid drive module will be occupy 15%, that means 4.8 Million. BorgWarner can provide comprehensive solution for P2 hybrid drive module including triple clutch module, control module, damper, P2 electric motor, power electronics and software.

-Continuously approach local OEMs

-Provide from components to modules to systems

-Provide compact and cost-effective P2 hybrid drive module